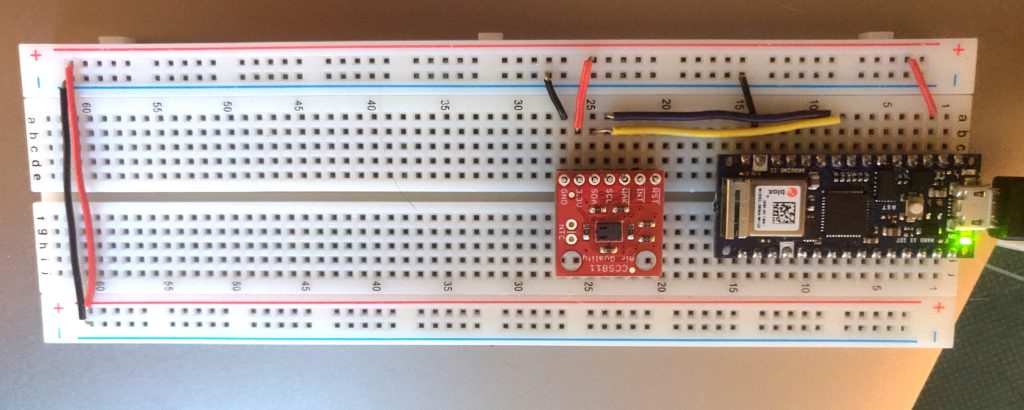

Time to dust off the blog, as a place to put things that don’t belong anywhere else during this quarantine. New York City’s closed all essential businesses, including my university, so like much of the world at the moment, I am working from home. This means a desk littered with electronic parts. It also means having to build circuits with no soldering iron, since I left it at the university.

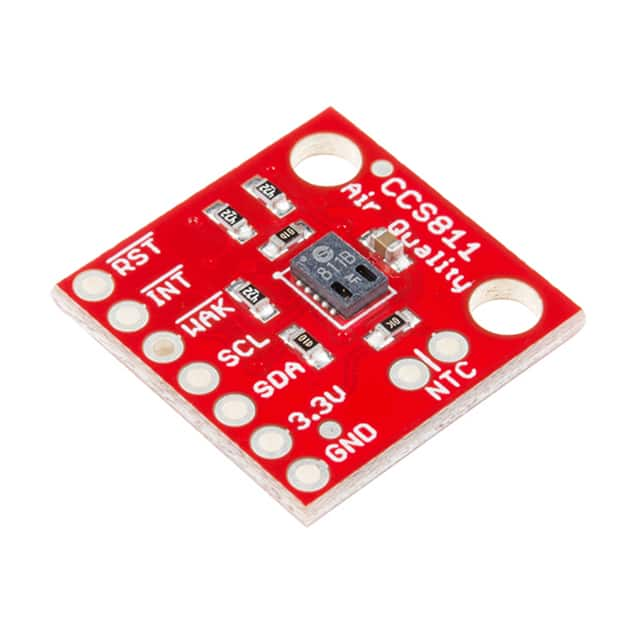

For many parts, no solder is no problem, but what do you do with something like your typical breadboard breakout board like this air quality sensor from Sparkfun? I could switch my whole system to other components like Grove or Qwiic, but that limits my options in terms of selection, and most importantly, I want to keep working with the through-hole components I’ve already got.

The answer: friction-fit header pins. These header pins have a loop at the tip that can be pushed tight into a typical header pin hole, forming a tight mechanical contact. They’re not perfect, and I will go back to soldering when I can, but for now, they’ll do the job.

Here are two press-fit options from Digikey, who seem to still be delivering at the moment:

- Samtec PHT-102-01-L-S (2 headers per row)

- Preci-dip 800-80-064-65-001101 (64 headers per row)

My other non-solder solution when I need to make a board I can throw around a bit is to use 22 AWG solid-core wires instead of stranded jumper wires. These used to be the standard for me, but in the past nine or ten years, flexible jumpers have taken over the maker electronics world. But they come out too easily, and if you’ve got a lot of clutter on your desk, they make for boards that easily get ruined. By cutting solid wire exactly to length and laying it flat on the board, you can make a more solid board. I usually keep at least red, black, blue, and yellow options in stock.